PE燃气管国际上把PE燃气管的材料分为PE32、PE40、PE63、PE80、PE100五个等级,而用于燃气管和给水管的材料主要是PE80和PE100。我国对聚乙烯管材专用料没有分级,这使得国内聚乙烯燃气管和给水管生产厂家选择原材料比较困难,也给聚乙烯管材的使用带来了不小的隐患。

因此国家标准局在GB/T13663-2000新标准中作了大量的修订,规定了给水管的不同级别PE80和PE100对应不同的压力强度,并且去掉旧标准中的拉伸强度性能,而增加了断裂伸长率(大于350%),即强调基本韧性。

PE燃气管执行标准:GB 15558.1-2003

燃气用PE管材是传统的钢铁管材、聚氯乙烯燃气的换代产品。

燃气管必须承受一定的压力,通常要选用分子量大、机械性能较好的PE树脂,如HDPE树脂。LDPE树脂的拉伸强度低,耐压差,刚性差,成型加工时尺寸稳定性差,并且连接困难,不适宜作为给水压力管的材料。但由于其卫生指标较高,LDPE特别是LLDPE树脂已成为燃气管的常用材料。LDPE、LLDPE 树脂的熔融粘度小,流动性好,易加工,因而对其熔体指数的选择范围也较宽,通常MI在0.3-3g/10min之间。

PE燃气管产品特点

良好的卫生性能:PE管加工时不添加重金属盐稳定剂,材质无毒性,无结垢层,不滋生细菌,很好地解决了城市饮用水的二次污染。

卓越的耐腐蚀性能:除少数强氧化剂外,可耐多种化学介质的侵蚀;无电化学腐蚀。

长久的使用寿命:在额定温度、压力状况下,PE管道可安全使用50年以上。

较好的耐冲击性:PE管韧性好,耐冲击强度高,重物直接压过管道,不会导致管道破烈。

可靠的连接性能:PE管热熔或电熔接口的强度高于管材本体,接缝不会由于土壤移动或活载荷的作用断开。

Shandong Wanji Plastic Co., Ltd.

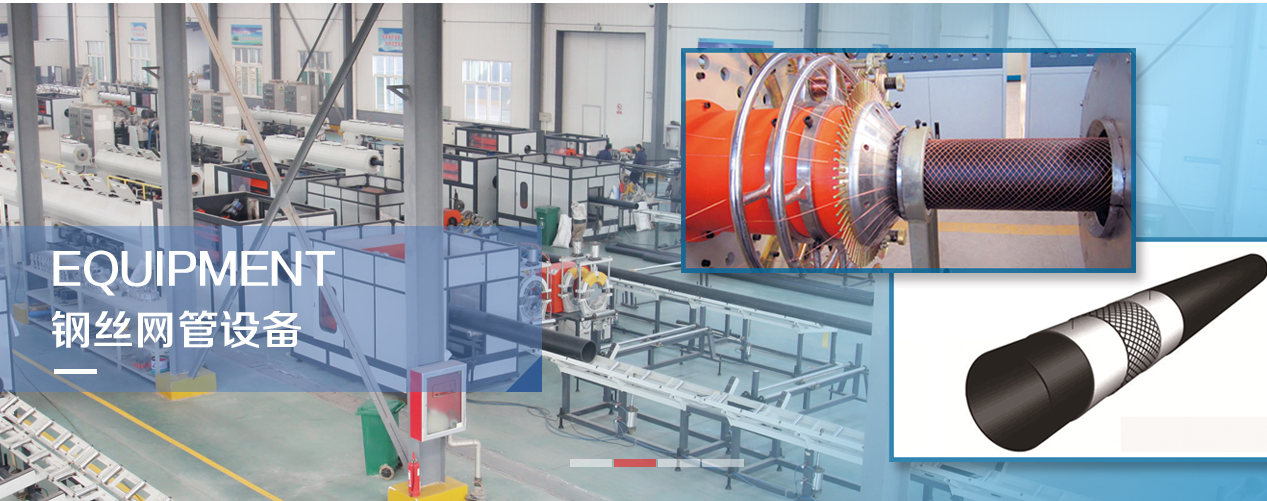

1.10 are produced by Battenfeld and Cincinnati, German: They can produce caliber 20mm-450mm pipes. Our advanced extrusion equipment not only ensures the full plasticization of raw materials, but also effectively prevents the excessive shear degradation of raw materials in the extrusion process, and fully exerts the performance of the raw materials, far higher than the national standards. It has created good conditions for the smooth construction of the pipe.

2. Imported online automatic measurement system and ultrasonic on-line detection device: Each of the company's PE pipe production line equipment is equipped with Innomax online weight control and wall-thickness measurement system, which truly guarantees the consistency of the wall thickness of the pipe.

3. Italian Baiwang raw material dehumidifying and drying system: the Company uses Italian Baiwang dehumidifying dryer, the best brand in the world, which quickly takes away the moisture from plastic raw materials. Eliminates the creation of air bubbles, enabling the product to achieve ideal mechanical, electrical, dimensional stability and appearance. Dehumidifier dryer air pipes are sealed circulatory system, and equipped with filters, so outside climate, in summer of high ambient humidity can be normal production, effectively prevent the production of defective products, greatly reduce the production of waste, and increase productivity.

4. Company's pipe fittings production: our company has 19 injection-molding equipment, that can produce 20mm-1200mm various pipe fittings. Among them, the largest injection-molding machine in China designed and manufactured by Zhejiang Tairui Machinery Co., Ltd. for our company. The maximum clamping force is 2800T, the maximum injection volume is 120,000 grams, and the injection molding diameter dn800mm is molded once. The quality has reached the international level. The level of the product. At present, the company's production of PE pipe has reached more than 600 kinds, fully complete series of supporting production.